Warehouse Inventory Management in CRM Software

Warehouse inventory management is a crucial part of a company’s warehouse management system. It helps monitor and control the quantity and value of inventory throughout business operations. Below are some important inventory management functions:

1. Tracking Inventory Quantity:

This function allows for recording and updating information about the current quantity of goods in the warehouse. When there are inbound or outbound transactions, the system updates the latest inventory quantities, helping managers know the remaining stock to avoid shortages or surpluses.

2. Monitoring Inventory Value:

This function allows for calculating and tracking the value of the inventory. The inventory management system stores price information for goods to calculate inventory value based on the quantity and corresponding prices. This gives managers an overview of the value of assets stored in the warehouse.

3. Defining Storage Locations:

This function records the exact location of each item in the warehouse. Using barcodes, SKU codes, or other coding systems, the inventory management system records the storage location of goods, enabling quick search and retrieval when needed.

4. Batch Management:

For businesses with goods of various origins and attributes, batch management is essential. It allows for recording information about batches, including production dates, expiration dates, quality information, and other attributes. This ensures that goods are used according to the FIFO (First In, First Out) principle or company regulations to avoid spoilage or issues related to the shelf life of goods.

5. Forecasting and Demand Management:

Warehouse inventory management also involves forecasting and managing the supply and demand of goods. Based on current inventory data, sales history, and other factors, the system can forecast future demand for goods. This helps managers plan production, order stock, and organize business activities efficiently.

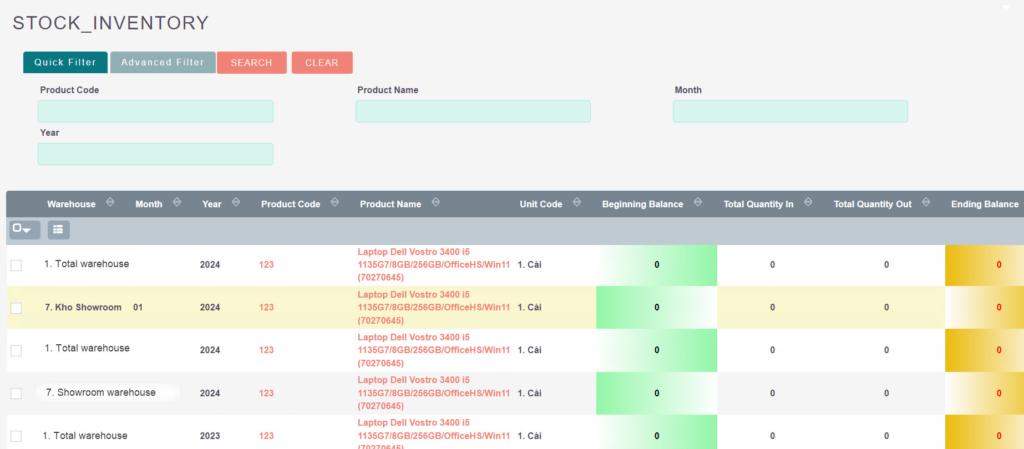

6. Reporting and Analysis:

This function enables the creation of reports and analysis on inventory status, inventory turnover, inventory value, and other performance indicators. These reports provide detailed information on the efficiency of inventory management, helping managers evaluate and make strategic decisions to optimize inventory management processes and enhance business performance.

In summary, Warehouse inventory management functions help track the quantity and value of goods in the warehouse, manage storage locations, handle batch management, forecast and manage supply and demand, and provide reporting and analysis. This helps businesses maintain appropriate inventory levels, meet customer demands, avoid shortages or surpluses, and optimize business operations.